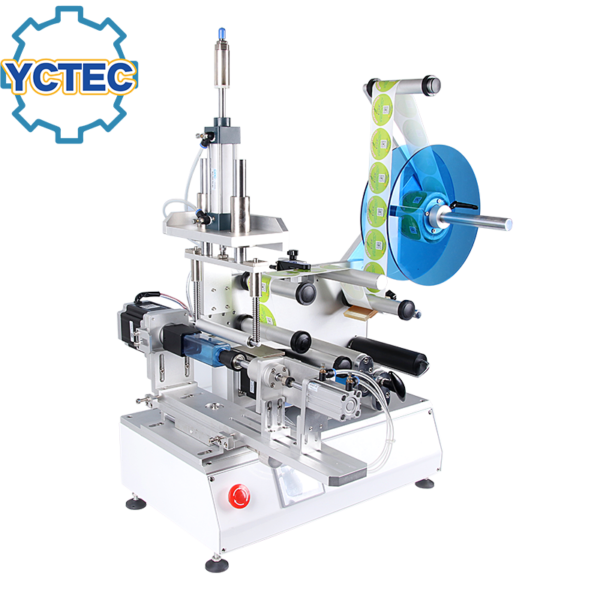

Plane Labeling Machine

Our plane labeling machines are engineered for accurate and efficient labeling on flat surfaces, ensuring high precision and consistency. Perfect for products like boxes, bags, and containers, these machines enhance productivity and reduce labeling errors. Discover our reliable and advanced solutions tailored to meet your flat surface labeling needs.

Your Trustful Plane Labeling Machine

YUCHENG is a renowned manufacturer of plane labeling machines in China, offering advanced solutions for precise labeling on flat surfaces. With years of expertise, we provide both automatic and semi-automatic machines tailored to handle a wide range of materials and applications. Our commitment to innovation and customization ensures that we can meet the unique demands of various industries. Reach out to us today for detailed product information or to request a personalized quote.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Plane Labeling Machine

Dongguan Yucheng Machinery Technology Co., Ltd. is located in the world factory – Dongguan, Guangdong. We are a high-tech enterprise integrating research and development, production and sales of labeling machines. We adopt electrical accessories of international famous brands, constantly optimize the mechanical structure, pay attention to each production link, to ensure the stability and durability of the machines.

Advantages of Plane Labeling Machine

- Accuracy

The plane labeling machine ensures precise label placement with an accuracy of ±0.1mm, making it ideal for applications requiring consistent and flawless labeling on flat surfaces.

- Versatility

This machine can handle a wide range of flat products, including boxes, pouches, and flat containers, accommodating various sizes and materials with ease.

- Ease of Operation

Designed with user-friendly controls, the plane labeling machine allows for quick setup and smooth operation, reducing training time and enhancing productivity.

- High Speed

With advanced automation, the machine delivers high-speed performance, significantly improving production efficiency and meeting the demands of large-scale operations.

- Customization

Plane labeling machines can be customized to suit specific industrial needs, such as unique label types, adhesive preferences, and varying product dimensions.

- Durability

Built with high-quality materials and a robust structure, these machines are designed to withstand rigorous industrial use, ensuring long-term reliability and reduced maintenance costs.

How Do Plane Labeling Machines Work?

Plane labeling machines function by placing products onto a conveyor or stationary platform where they are aligned for labeling. As the product moves or stays in position, a label is dispensed from a roll or applicator and pressed onto the flat surface with precision.

The system ensures smooth and accurate label application without wrinkles or misplacement, making it suitable for a variety of flat products such as boxes, cartons, and pouches. This efficient process is compatible with different product sizes and label types, offering reliable performance for industries demanding high-quality labeling. For more insights, visit our blog on plane labeling machines.

What Are Plane Labeling Machines Used For?

Plane labeling machines are extensively used in industries that require accurate and consistent labeling on flat surfaces. These machines are ideal for applications in sectors such as electronics, cosmetics, food packaging, and manufacturing, where precise labeling is critical for branding, compliance, and efficient product identification.

They are particularly well-suited for products like boxes, pouches, flat containers, and packaging sheets. However, they are less effective for cylindrical or irregularly shaped items that require specialized labeling techniques.

Design and Planning

Engineers begin by designing the machine based on specific customer requirements, including product dimensions, label types, and production speed. Detailed blueprints are created using CAD software to ensure the machine meets industry standards and fulfills operational needs.

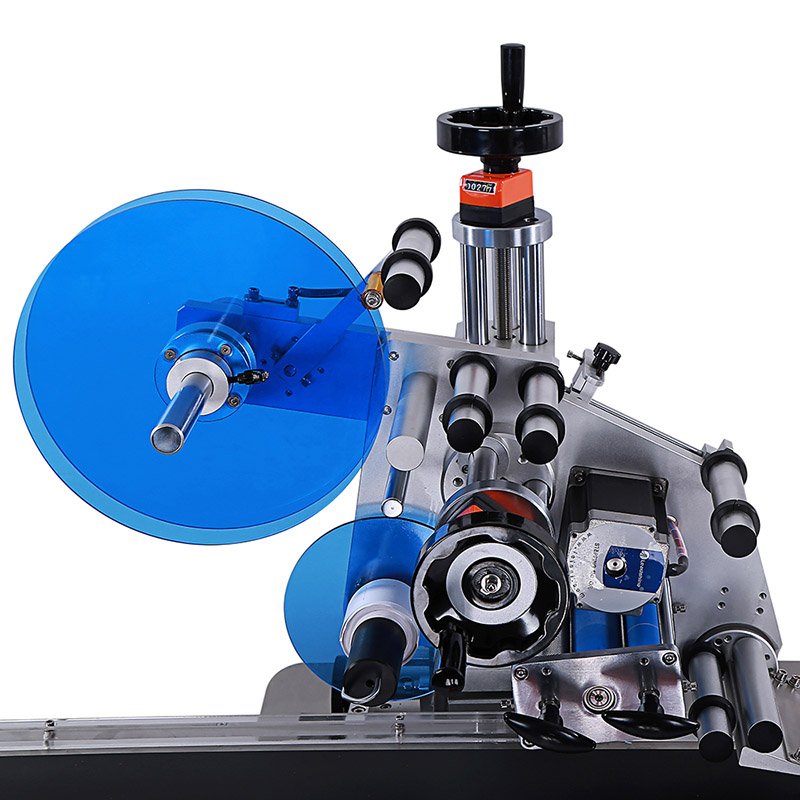

Component Selection

Key components such as motors, sensors, conveyors, and label applicators are sourced for their durability and precision. Materials like stainless steel and industrial-grade plastics are chosen to ensure the machine’s longevity and reliability in demanding environments.

Frame Fabrication

The machine’s frame is constructed from strong and corrosion-resistant materials like stainless steel or aluminum. The frame provides a stable base for mounting all components and is designed to facilitate easy cleaning and maintenance.

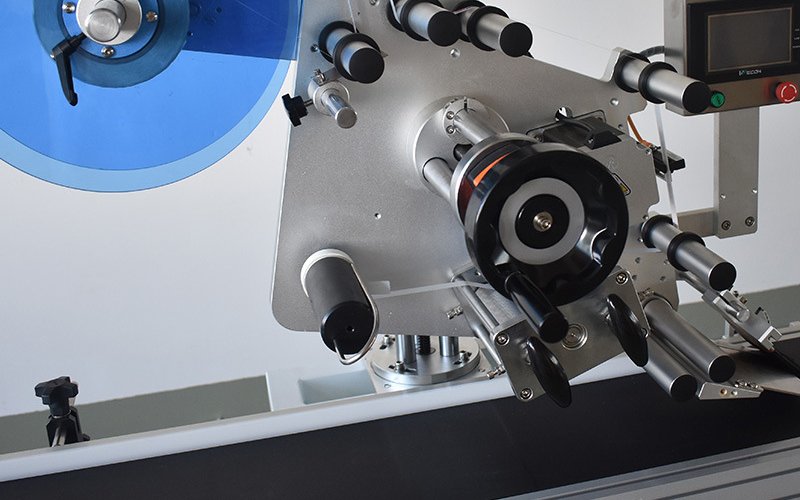

Assembly of Components

Critical parts such as the conveyor system, label applicators, and sensors are installed onto the frame. Wiring and pneumatic systems are integrated, and components are meticulously aligned to guarantee smooth and efficient operation.

Programming and Calibration

The control system is programmed to regulate machine functions, including label positioning, product alignment, and operational speed. Sensors and applicators are calibrated to ensure precise and consistent label placement during production.

Testing and Quality Control

The completed machine is subjected to rigorous testing with sample products and labels. Any issues are identified and resolved to optimize performance. Once the machine passes all quality control checks, it is packaged and prepared for delivery to the customer.

Plane Labeling Machine Designs: Factors to Consider

#1 Product Shape and Size Compatibility

The size and shape of the products to be labeled are fundamental to the design of a plane labeling machine. Machines should handle a range of flat surfaces, including varying widths and lengths. Adjustable fixtures and modular designs can enhance adaptability for different product dimensions.

#2 Label Type and Material

Plane labeling machines must accommodate various label types, including paper, plastic, and metallic foils. The adhesive properties and thickness of labels influence the design of the application mechanism. Flexibility to handle different label materials ensures greater operational versatility.

#3 Product Positioning System

Precise positioning of products is essential for accurate labeling on flat surfaces. Features like alignment guides, adjustable jigs, and anti-slip mechanisms contribute to consistent performance. The positioning system must ensure stability for products of different sizes and materials.

#4 Labeling Speed and Accuracy

The labeling machine must meet production speed requirements while maintaining precision. High-speed models often incorporate sensors and automated alignment systems for exact label placement, reducing material waste and enhancing efficiency.

#5 Machine Durability and Maintenance

Plane labeling machines are typically constructed with robust materials, such as stainless steel, to ensure durability and longevity. This is particularly important in industries like packaging, food, and cosmetics. Designs that facilitate easy maintenance and cleaning improve overall usability.

#6 Compliance with Industry Standards

Regulatory compliance is critical to ensure the machine operates safely and meets industry-specific requirements. Adherence to standards not only enhances reliability but also reduces operational risks, particularly in highly regulated sectors like pharmaceuticals and food production.

Plane Labeling Machine by Automation Classification

Semi-auto Plane Labeling Machine

The semi-auto plane labeling machine is designed for cost-effective labeling on flat surfaces in small to medium-sized production lines. Operators manually place the products in position, and the machine applies labels with precision. Ideal for businesses requiring flexibility, it supports a variety of product sizes and label materials. Its straightforward setup, minimal maintenance, and reliable performance make it a popular choice in industries such as food, cosmetics, and electronics, where versatility and affordability are key.

Automatic Plane Labeling Machine

The automatic plane labeling machine is tailored for high-speed, hands-free labeling on flat surfaces, perfect for large-scale production environments. This machine automatically feeds, aligns, and labels products, minimizing manual intervention and maximizing efficiency. It can handle a diverse range of product sizes and label types, ensuring consistent and accurate label placement. Widely used in industries such as packaging, pharmaceuticals, and consumer goods, it is ideal for high-volume operations demanding precision and reliability.

Request A free quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 186 6414 0847

- Amy@3yct.com