Ever stood beside a bottle labeling machine? I remember the first time I did—it was like watching a well-rehearsed dance, with bottles gliding by and labels wrapping around them flawlessly.

A bottle labeling machine works by automatically applying labels to bottles using precise mechanisms. It aligns each bottle, applies adhesive labels at high speeds, and ensures consistent placement, boosting efficiency in packaging operations.

Fascinating how something so complex can seem so effortless, right?

How Does a Bottle Labeling Machine Work?

I still get a thrill watching these machines in action.

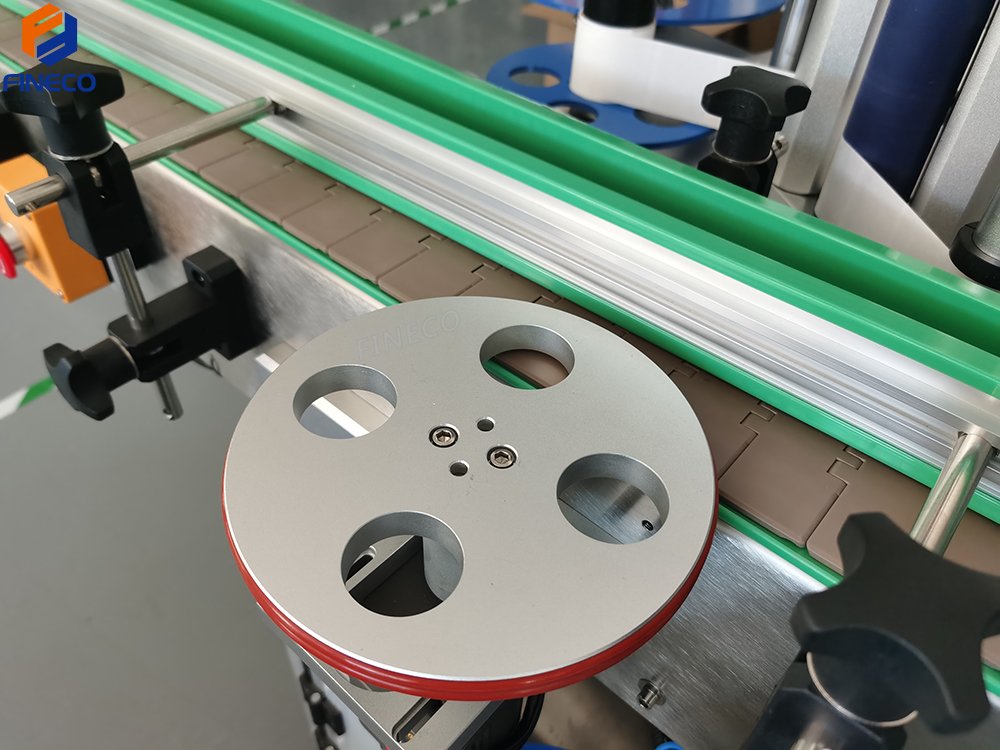

A bottle labeling machine operates by feeding bottles through a conveyor system where they're precisely positioned. Labels are dispensed and applied using rollers or brushes, adhering smoothly without wrinkles or bubbles.

The Inner Workings of Automatic Labeling Machines

At the heart of an automatic labeling machine is synchronization:

- Bottle Feeding: Bottles enter the machine via a conveyor.

- Alignment: Guides position each bottle correctly.

- Label Dispensing: Labels are released from a roll or magazine.

- Application: Labels are applied using a label applicator.

- Pressing: Rollers ensure the label sticks firmly.

Here's a quick table to illustrate:

| Component | Function |

|---|---|

| Conveyor Belt | Moves bottles through the machine |

| Sensors | Detect bottle positions |

| Label Applicator | Applies labels accurately |

| Rollers/Brushes | Secure labels onto bottles |

These high-speed labeling machines can handle thousands of bottles per hour. It's like having a tireless assistant who never makes mistakes.

How Does a Bottle Machine Work?

Sometimes people ask me, "Is a bottle machine just for labeling?" Well, there's more to it.

A bottle machine refers to equipment that automates various bottling processes—filling, capping, and labeling. It streamlines production by coordinating these tasks efficiently.

The Symphony of Automation

Imagine an orchestra where each instrument plays in harmony:

- Filling Station: Bottles are filled with the product.

- Capping Station: Caps are placed and secured.

- Labeling Station: Labels are applied precisely.

This coordination ensures products are packaged swiftly and consistently. It's essential for businesses looking to scale up without sacrificing quality.

How Does a Label Printing Machine Work?

Printing labels is an art form I've grown to appreciate deeply.

A label printing machine creates labels by transferring ink onto various materials using methods like thermal transfer or inkjet printing. It allows for customized, high-quality labels in large quantities.

From Design to Physical Label

Here's how it unfolds:

- Design Creation: The label design is crafted using software.

- Material Selection: Choosing the right label stock and adhesive.

- Printing Process: The machine prints the design onto the label material.

- Quality Check: Ensuring each label meets standards.

Printing Methods Comparison

| Method | Advantages | Considerations |

|---|---|---|

| Thermal Transfer | Durable, long-lasting labels | Requires ribbon replacement |

| Inkjet Printing | High-quality images/colors | Higher ink costs |

These machines are vital for producing labels that not only inform but also attract customers—think of the eye-catching labels on craft beer bottles.

How Does a Label Applicator Work?

Label applicators might seem humble, but they're game-changers.

A label applicator is a device that applies labels to products or packaging. Using sensors and precise mechanisms, it ensures labels are placed accurately, often integrating seamlessly with conveyor systems.

The Precision Tool in Packaging

What makes label applicators, including small labelers, so effective?

- Versatility: They handle various product sizes and shapes.

- Efficiency: Increase throughput with minimal errors.

- Consistency: Ensure each label is placed perfectly.

Types of Label Applicators

| Type | Best For |

|---|---|

| Wipe-On | Flat or slightly curved surfaces |

| Tamp-Blow | Irregular or delicate items |

| Air-Blow | High-speed applications |

Whether it's an automatic bottle labeling machine for sale or a specialized beer bottle labeler, these applicators are the unsung heroes of packaging.

https://youtu.be/DhTbzkjc7R0?si=LBVg1fql_2Ga-IYM

Conclusion

It's amazing how these machines—once mysterious contraptions to me—have become tools I work with every day. Understanding how they operate not only satisfies my curiosity but also helps me appreciate the innovation behind every labeled bottle on the shelf.