High-speed labeling machines are marvels of modern manufacturing. They ensure precise, consistent labeling at a rapid pace, making them invaluable for industries like food, beverage, and pharmaceuticals.

How does a high-speed labeling machine work?

A high-speed labeling machine operates using an automated process that involves feeding products onto a conveyor, detecting their position with sensors, and applying pre-printed labels accurately. The machine synchronizes label application with product movement, ensuring consistent placement even at high speeds. Advanced features, such as adjustable settings for different bottle shapes (e.g., round bottle labeling machine), make these machines versatile for various applications.

Understanding the nuances of labeling technology ensures better operational efficiency.

How does a labeler machine work?

Labeler machines streamline product identification by attaching labels with speed and precision. They form the backbone of efficient packaging lines in industries requiring automated solutions.

How does a high-speed labeler work?

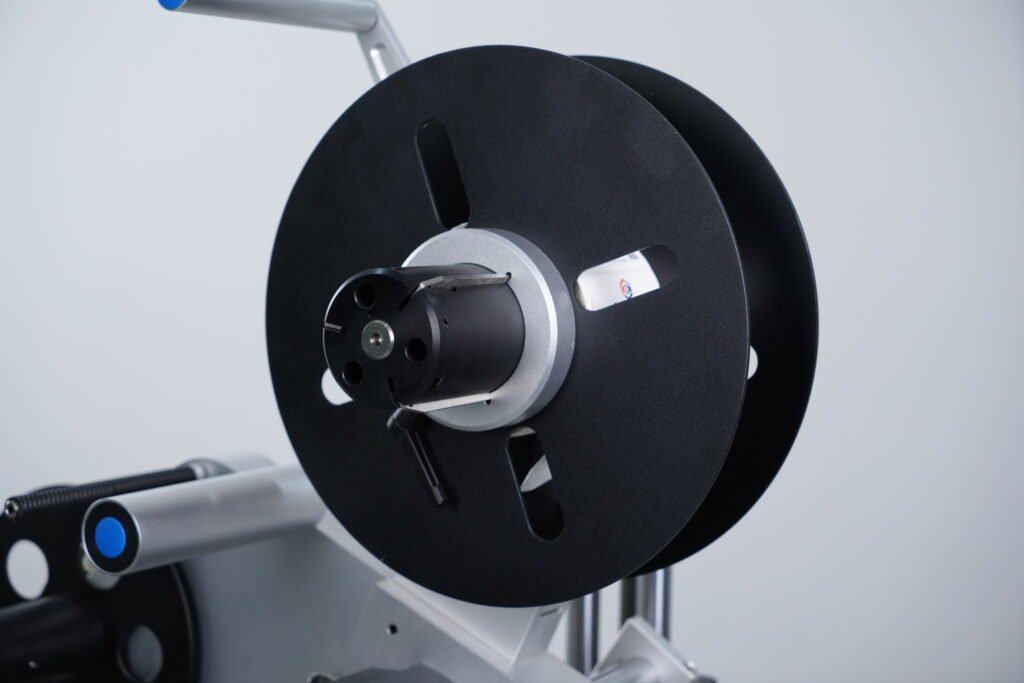

A high-speed labeler aligns products on a conveyor, scans their position with sensors, and applies labels from a rotating reel. Each step, from peeling the label to adhesion, is coordinated for flawless placement. Advanced models, like round bottle labeling machines, handle curved surfaces efficiently.

Dive deeper: The components of a labeler machine

High-speed labeling machines consist of key components like a conveyor, label dispenser, and sensors.

- Conveyor system: Transports products for labeling.

- Label applicator: Releases and applies labels smoothly.

- Sensors: Detect product position and ensure timing accuracy.

Modern machines feature adjustability for diverse shapes and sizes, like beer bottles or small containers. They also incorporate error-detection systems to minimize waste. Below is a comparison table highlighting their versatility:

| Feature | Round Bottle Labeling Machine | Beer Bottle Labeler | Small Labeler |

|---|---|---|---|

| Product Type | Round bottles | Beer bottles | Small items |

| Speed | Up to 200 BPM | 150 BPM | 100 BPM |

| Price Range | Mid to high | Mid | Low to mid |

| Key Benefit | High-speed precision | Beverage labeling | Cost-effective |

How do label applicators work?

Label applicators attach labels to various surfaces during production, ensuring quality and consistency.

What is the working mechanism of label applicators?

A label applicator uses rollers, a peel plate, and a dispensing mechanism to apply labels. The machine peels the label backing and adheres it to products with pressure or air-assisted techniques.

Dive deeper: Choosing the right label applicator

Choosing the right label applicator involves analyzing factors like speed, product type, and automatic labeling machine price. For example, an automatic bottle labeling machine can improve productivity in beverage production. Key aspects to consider include:

- Labeling Speed: Ensure the machine matches production volume.

- Material Compatibility: Certain applicators handle delicate labels better.

- Integration Options: Machines must fit existing production lines seamlessly.

Industry-specific solutions like beer bottle labelers or automatic labeling machines for sale offer tailored features to meet specific demands.

How do label dispensers work?

Label dispensers are compact machines designed for simpler tasks like small-scale labeling.

How does a label dispenser operate?

A label dispenser uses a motorized roller to separate a label from its backing paper. It positions the label for easy application manually or semi-automatically.

Dive deeper: Manual vs. automatic label dispensers

Manual dispensers are cost-effective but require human effort. Automatic dispensers, often part of larger systems, enhance speed and accuracy. Here’s a comparison:

| Feature | Manual Dispenser | Automatic Dispenser |

|---|---|---|

| Speed | Moderate | High |

| Precision | Dependent on user | Consistent |

| Cost | Low | Higher initial investment |

What does a labeler do?

Labelers apply labels to products efficiently, enhancing brand visibility and regulatory compliance.

What is the purpose of a labeler?

The primary purpose of a labeler is to affix labels quickly and precisely. High-speed labeling machines can handle large volumes, perfect for industries like cosmetics, beverages, and pharmaceuticals.

Dive deeper: The importance of high-speed labeling

High-speed labelers, like automatic bottle labeling machines, enable businesses to meet demanding schedules without compromising quality. They accommodate diverse product types, from round bottles to rectangular packages.

Modern labelers integrate features like:

- Adjustable speed settings for varying production rates.

- Error detection systems to avoid mislabeling.

- Flexible design for compatibility with multiple product sizes.

Investing in advanced systems ensures efficiency and scalability, making them essential for competitive industries.

It's a video for your reference:

https://youtube.com/shorts/h2Fq7OWvcFk?feature=share

Conclusion

Understanding high-speed labeling machines helps optimize production. Whether it's a round bottle labeling machine or a beer bottle labeler, these systems streamline operations, ensuring precision and speed.