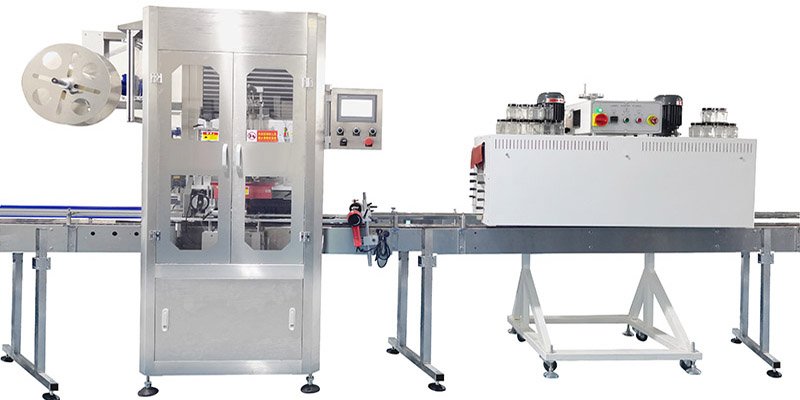

Label applicators are vital tools in the packaging industry, ensuring products are professionally labeled efficiently. Various types suit different needs, offering flexible solutions across industries.

Label applicators come in various types, including pressure-sensitive, shrink-sleeve, heat transfer, and thermal labelers. Each type caters to specific applications, such as bottles, cartons, or flexible packaging. Machines range from manual small labelers to high-speed automatic labeling machines for sale. Advanced models like round bottle labeling machines and beer bottle labelers provide precision and reliability, tailored to diverse industries and budgets. Understanding these types helps businesses optimize their labeling processes.

Label applicators simplify operations and enhance product presentation. Let’s explore the types of labels and applicators in detail.

What are the 4 types of labels?

Labels serve different purposes and are categorized into key types, each suited for specific products.

The four main types of labels are pressure-sensitive, shrink sleeve, thermal, and heat transfer. Pressure-sensitive labels are widely used due to their adhesive backing, while shrink-sleeve labels offer 360-degree coverage for unique designs. Thermal labels are cost-effective for short-term uses, and heat-transfer labels provide durable, long-lasting results.

Types of Labels in Packaging

Labels play a crucial role in branding and product information. Here's a breakdown of the four key types:

| Type | Application |

|---|---|

| Pressure-Sensitive | Versatile, used for bottles, cartons, and jars. |

| Shrink Sleeve | Full coverage for curved surfaces, e.g., round bottles. |

| Thermal | Cost-effective, used for shipping or temporary product labels. |

| Heat Transfer | Long-lasting labels, ideal for high-quality packaging like beer bottles. |

Each type suits specific industries, such as food, beverage, or logistics. For example, a beer bottle labeler often uses shrink sleeves or pressure-sensitive labels, ensuring high durability and appealing visuals.

What are the different types of label machines?

Label machines are categorized based on their function and automation level, from manual to fully automatic models.

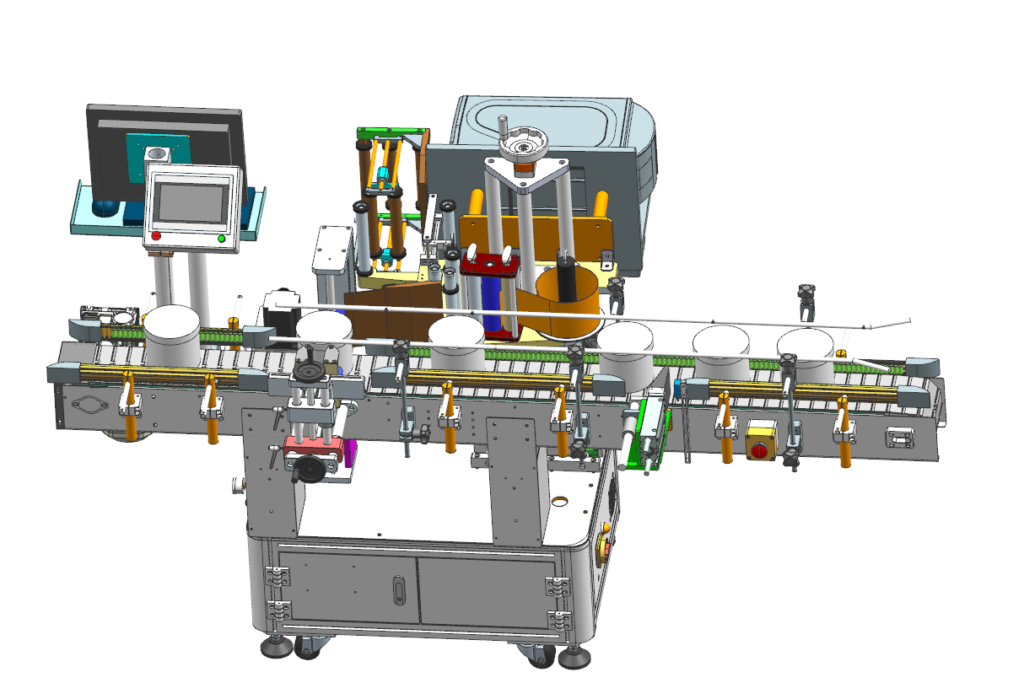

Label machines include manual labelers, semi-automatic, and fully automatic labeling machines. Round bottle labeling machines are tailored for cylindrical containers, while high-speed machines suit large-scale operations. Industries often use an automatic bottle labeling machine for sale due to its efficiency and customization. These machines can handle different materials and container shapes with precision.

Key Labeling Machine Categories

Understanding the types of labeling machines ensures you select the right one for your needs:

| Machine Type | Features |

|---|---|

| Manual Labeler | Hand-operated, suitable for small-scale operations. |

| Semi-Automatic | Balances manual setup with automation, ideal for medium-scale production. |

| Automatic Labeler | Fully automated, customizable, high-speed. Common in beverage and pharma. |

| Round Bottle Labeler | Specializes in cylindrical containers, such as wine or beer bottles. |

Automatic labeling machine prices vary based on features, but they save time and reduce errors, making them a cost-effective choice for growing businesses.

What is a label applicator?

Label applicators are machines or tools that attach labels to products, streamlining the packaging process.

A label applicator is a device that applies labels to products automatically or semi-automatically. These machines improve accuracy, speed, and consistency. Common types include small labelers for compact items, beer bottle labelers for curved surfaces, and automatic machines for high-volume labeling. They cater to industries like food, cosmetics, and logistics.

Features of Label Applicators

Modern label applicators integrate advanced features to meet industry demands:

- Versatility: Supports a wide range of label types and container shapes.

- Precision: Ensures accurate placement to enhance product appearance.

- Speed: High-speed labeling machines increase production efficiency.

- Cost Savings: Reduces labor costs and waste from mislabeling.

An automatic bottle labeling machine can handle diverse tasks, from labeling small items to bulk packaging. These machines are widely adopted due to their durability and adaptability.

What are the different types of thermal labels?

Thermal labels vary based on printing methods and intended applications, offering tailored solutions for businesses.

Thermal labels include direct thermal and thermal transfer types. Direct thermal labels are cost-effective and used for temporary labels, while thermal transfer labels are durable and suited for long-term applications. Both types are compatible with automatic labeling machines, supporting industries like logistics, healthcare, and retail.

Thermal Label Options

Choosing the right thermal label depends on your needs:

| Type | Features | Applications |

|---|---|---|

| Direct Thermal | No ink, short-term use, sensitive to heat. | Shipping labels, receipts. |

| Thermal Transfer | Ink ribbon required, resistant to heat and wear. | Product labels, asset tags. |

Both types are integral to automated systems, such as high-speed labeling machines, ensuring quality output and efficient operations.

Conclusion

Label applicators and types of labels form the backbone of efficient packaging. Choosing the right machine and label type enhances productivity, accuracy, and product appeal.