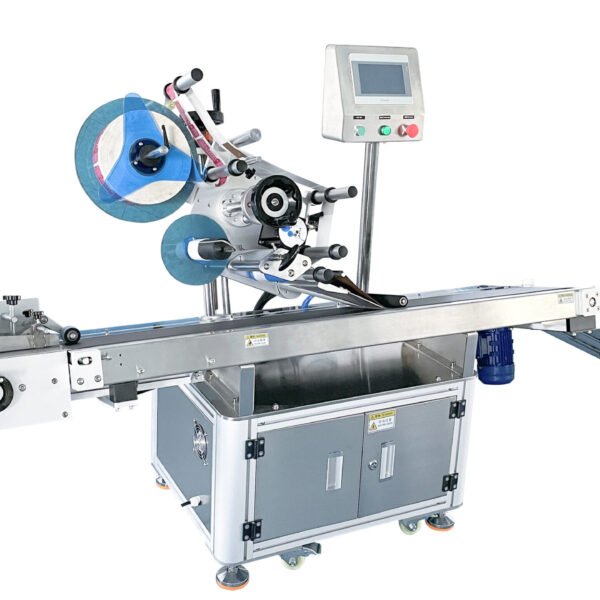

Automatic Card Labeling Machine

Our Automatic Card Labeling Machines offer high-speed and precise labeling for cards of various sizes, ensuring efficiency and accuracy. Perfect for applications like loyalty cards, business cards, and ID cards, these machines streamline your labeling process. Discover our advanced labeling solutions designed to meet your specific production needs

Your Trustful Automatic Card Labeling Machine

Our Automatic Card Labeling Machine is designed to automate the labeling process for cards, including credit cards, ID cards, and membership cards. It ensures high-speed and precise label application on flat surfaces, enhancing productivity and reducing manual labor. The machine is equipped with advanced sensors and an intuitive control system to ensure accurate placement of labels, even on high-volume production lines. Ideal for industries such as banking, retail, and membership services, the Automatic Card Labeling Machine guarantees a consistent, efficient labeling process with minimal operator intervention. It is engineered to handle various card sizes and materials, providing reliable solutions for mass card production and packaging.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Automatic Card Labeling Machine

The Automatic Card Labeling Machine is designed for high-speed, precise labeling of cards such as credit cards, loyalty cards, and membership cards. This machine automates the entire labeling process, ensuring labels are applied to cards with consistent alignment and accuracy. It features a user-friendly interface, adjustable settings for different card sizes and label types, and an advanced sensor system that ensures optimal label placement. Widely used in industries such as banking, retail, and membership services, the Automatic Card Labeling Machine streamlines production, reduces labor costs, and improves overall labeling efficiency, making it the ideal choice for high-volume operations.

Advantages of Automatic Card Labeling Machine

- High-Speed Labeling

The Automatic Card Labeling Machine can apply labels at high speeds, significantly increasing throughput. This high-speed capability is ideal for mass production environments, ensuring fast and efficient labeling of large volumes of cards.

- Accurate

Equipped with advanced sensors and guides, the machine ensures precise and consistent label placement on each card, eliminating the risk of misalignment and ensuring high-quality results every time.

- Reduced Labor Costs

By automating the labeling process, the machine reduces the need for manual labor, helping to cut down on production costs and minimize human error, improving operational efficiency.

- Versatility

The machine can handle a variety of card sizes, making it highly adaptable to different types of cards, including ID cards, membership cards, and loyalty cards, ensuring a wide range of applications.

- User-Friendly Interface

The Automatic Card Labeling Machine is designed with an intuitive interface that allows operators to easily adjust settings such as labeling speed, card size, and label types, offering convenience and flexibility.

- Durable and Reliable

Built with high-quality materials and designed for continuous operation, the Automatic Card Labeling Machine is durable and reliable, capable of handling high-volume production runs with minimal maintenance.

How Do Automatic Card Labeling Machine Work?

The Automatic Card Labeling Machine works by automatically feeding cards through a conveyor system, where they are positioned and aligned with precision. Sensors and guides ensure each card is accurately placed for labeling. Once the card reaches the labeling station, an applicator applies the label to the designated area.

The label is then smoothed onto the card using pressure rollers, ensuring proper adhesion and preventing wrinkles or air bubbles. The machine is equipped with adjustable settings, allowing it to handle different card sizes and label materials. After labeling, the cards are directed to the next stage in the production line, whether for packaging or further processing.

What Are Automatic Card Labeling Machine Used For?

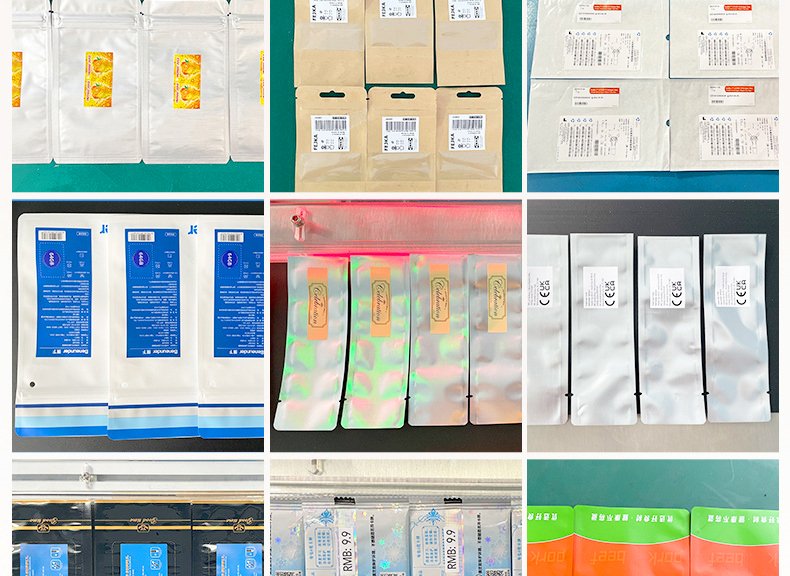

Automatic Card Labeling Machines are used to apply labels to various types of cards, such as credit cards, identification cards, membership cards, and loyalty cards. The labels typically include product information, logos, barcodes, or QR codes, providing clear identification and traceability.

These machines are widely used in industries such as banking, retail, telecommunications, and membership services, where high-volume production and precise labeling are essential. By automating the process, they help to speed up production, reduce costs, and ensure consistent and professional-looking results with minimal human intervention.

Design and Planning

Engineers begin by designing the Automatic Card Labeling Machine to meet specific production requirements, including card dimensions, label types, and labeling speeds. Detailed CAD blueprints are created to optimize the machine’s layout for efficient operation and accurate label placement.

Component Manufacturing

The various components of the machine, including conveyors, label applicators, sensors, and rollers, are manufactured using advanced technologies to ensure high-quality performance and durability.

Assembly

After the components are produced, the machine is assembled. This involves the integration of mechanical parts with electrical systems, ensuring the smooth operation of sensors, controls, and applicators.

Software Integration

Custom software is programmed into the machine to control labeling processes, speed adjustments, and sensor operations. This software ensures that the machine can handle different card sizes and label types with ease.

Testing and Calibration

The machine undergoes rigorous testing to verify its functionality, ensuring that all systems operate correctly. Calibration is performed to ensure precise label placement and optimal adhesion.

Quality Control and Inspection

The final machine is thoroughly inspected for quality, durability, and performance, making sure it meets all design specifications before being shipped to customers.

Packaging and Delivery

Once inspected, the Automatic Card Labeling Machine is packaged carefully for delivery. Along with the machine, all necessary manuals, maintenance guides, and technical support information are provided.

Automatic Card Labeling Machine Designs: Factors to Consider

#1 Card Size and Shape

The design of the machine must accommodate a range of card sizes, from standard ID cards to custom-sized membership cards. Adjustable fixtures and guides ensure accurate labeling, regardless of card dimensions.

#2 Label Type and Material

The machine should be able to handle various types of labels, such as paper, plastic, or holographic materials. The design must ensure that different labels adhere properly without wrinkling or peeling.

#3 Production Speed

The design must account for the desired labeling speed to meet production demands. High-speed operation is essential for large-scale card production, so the machine’s components must be optimized for quick, continuous performance.

#4 Accuracy and Precision

Given the small and delicate nature of cards, the design should ensure precise label placement. Advanced sensors and guides help achieve high alignment accuracy, ensuring that each card is labeled consistently.

#5 Ease of Integration

The machine should be designed to integrate smoothly with existing production lines, minimizing disruption and providing a seamless workflow from card production to packaging.

#6 Durability and Maintenance

The materials used in the design should be durable and capable of withstanding continuous operation. The design must also allow for easy maintenance and quick troubleshooting in case of issues.

#7 User-Friendly Interface

The design should include an intuitive control panel that allows operators to adjust settings easily, such as speed, label positioning, and card size. This ensures minimal training and operational efficiency.

Automatic Card Labeling Machine by Automation Classification

Semi-auto Automatic Card Labeling Machine

The Semi-Automatic Card Labeling Machine is designed for smaller production runs or businesses with moderate labeling needs. Operators manually load the cards into the machine, and the machine automatically applies the labels with precision. This model offers flexibility and control over the labeling process while reducing labor costs. It’s ideal for low to medium-volume card labeling, providing high accuracy and reliability without the need for full automation.

Automatic Automatic Card Labeling Machine

The Fully Automatic Card Labeling Machine is designed for high-volume production environments. The machine automates the entire process from card loading to label application, significantly reducing the need for operator intervention. It features a fully integrated system with advanced sensors and controls that allow for fast, accurate, and consistent labeling. Ideal for large-scale card production, this machine improves efficiency, reduces labor costs, and ensures high-quality results across large quantities of cards.

Request A free quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 186 6414 0847

- Amy@3yct.com