You know, there's something almost therapeutic about watching a labeling machine in action—it's like witnessing a well-orchestrated ballet of mechanics. But I'll be honest, the idea of labeling plastic buckets used to make me break out in a cold sweat. I still remember standing in front of a mountain of unlabeled buckets, thinking, "There has to be a better way." Spoiler alert: there is.

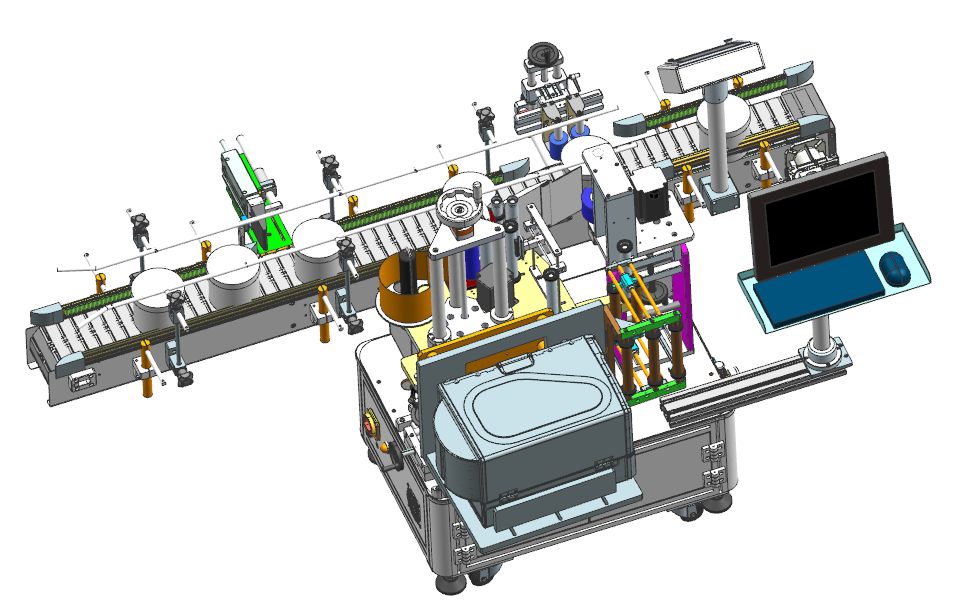

If you're looking to label plastic buckets effectively, an automatic labeling machine designed for round containers is your best friend. These machines handle various bucket sizes, applying labels smoothly and efficiently. Opt for a high-speed labeling machine that fits your bucket's dimensions, and make sure to adjust the label applicator correctly to avoid wrinkles or misalignment. Trust me, with the right setup, you'll wonder how you ever managed without it.

But let's dive deeper—I’ve got some stories and tips that might just make your labeling journey a whole lot smoother.

How to Labeling on Plastic Bucket?

I recall a time when a close friend in the industry called me in a panic. "I've got hundreds of plastic buckets to label by the end of the week!" she exclaimed. We've all been there, right? The sheer volume can be overwhelming.

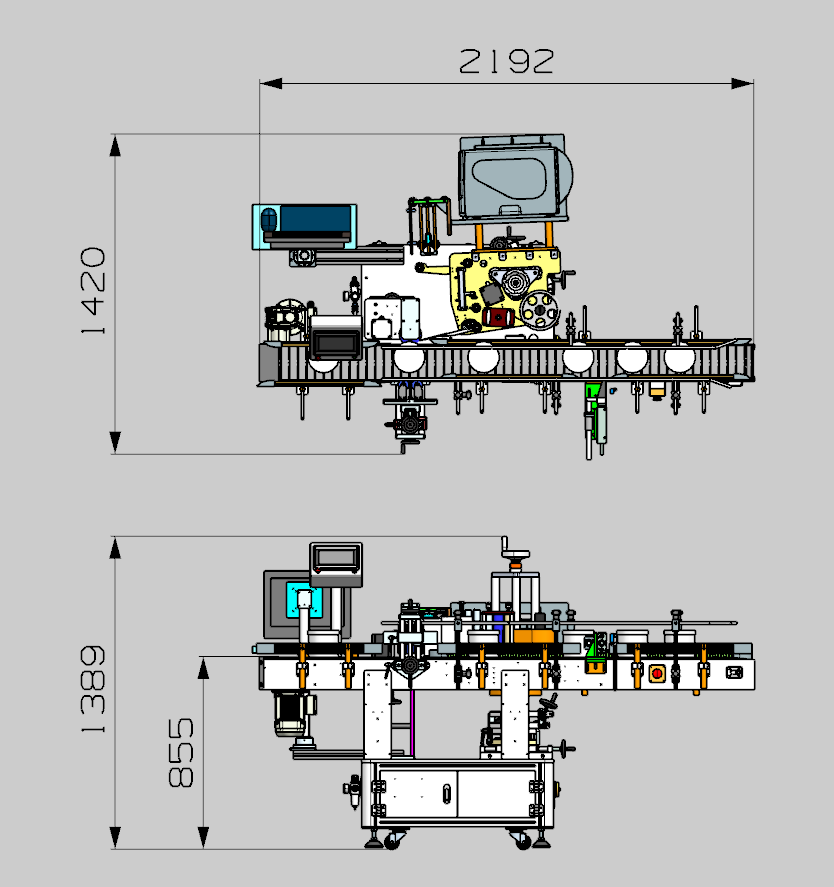

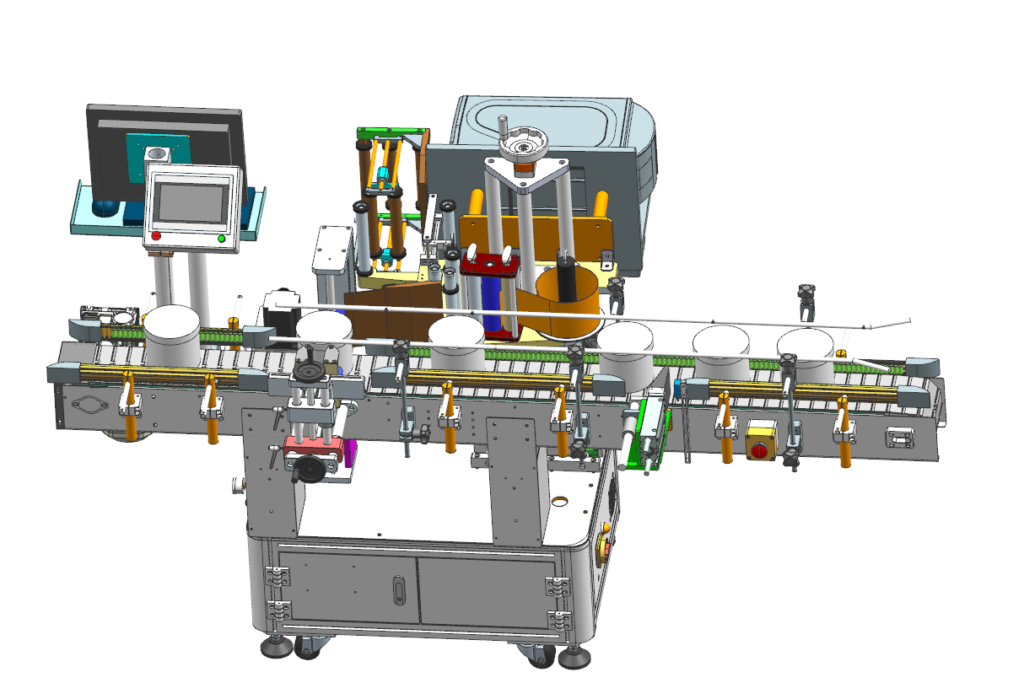

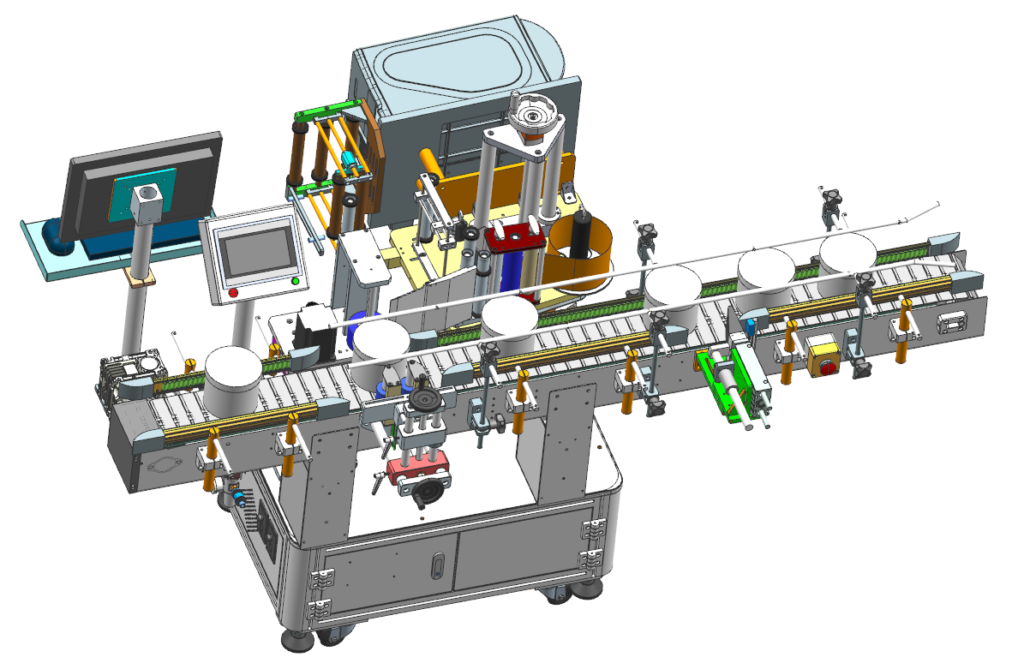

To label a plastic bucket, use a bucket labeling machine designed for round or irregular shapes. Adjust the machine settings to match the bucket's size, ensuring the label wraps evenly without bubbles or creases.

Choosing the Right Machine

Finding the right labeling machine is like finding the perfect pair of shoes—it needs to fit just right.

- Look for Machines Designed for Buckets: Not all labelers are created equal. Those specifically made for buckets handle the size and weight effortlessly.

- Adjustability is Key: Buckets come in all shapes and sizes. A machine that you can fine-tune makes life so much easier.

- High-Speed Options: If you're dealing with large quantities, a high-speed labeling machine saves both time and sanity.

Personal Tip: Test Before You Commit

Before diving in headfirst, always do a test run. I learned this the hard way after ending up with a batch of misaligned labels—not my finest hour.

Overcoming Common Challenges

Handles, ridges, and textured surfaces can be tricky, but they're not deal-breakers.

- Use Flexible Labels: They conform better to the bucket's surface.

- Strong Adhesives: Essential for labels to stay put, especially on textured plastic.

Quick Reference Table

| Machine Feature | Importance |

|---|---|

| Adjustable Settings | High |

| High-Speed Capability | Medium to High |

| Handles Irregular Shapes | High |

Sometimes, it's the little tweaks that make all the difference. With the right machine and a bit of patience, labeling plastic buckets becomes a breeze.

How to Label 1-Gallon Buckets Automatically?

Ah, the classic 1-gallon bucket—a staple in so many industries. I used to think automating their labeling was overkill until I saw the efficiency gains firsthand.

To label a 1-gallon bucket automatically, use an automatic labeling machine capable of handling larger containers. Adjust the machine settings for the bucket's dimensions to ensure precise label application without manual intervention.

The Game-Changer: Automation

Switching to an automatic labeling machine felt like upgrading from a bicycle to a car. Suddenly, what took hours could be done in minutes.

- Increased Efficiency: High-speed labeling machines can process hundreds of buckets per hour.

- Consistency is King: Automatic machines apply labels uniformly, enhancing product appearance.

My Experience with Automatic Labelers

I'll never forget the relief I felt after automating our labeling process. Not only did it free up time, but it also reduced errors significantly.

Tips for Success

- Proper Calibration: Spend time setting up the machine correctly—it pays off.

- Regular Maintenance: Keep your machine in tip-top shape to avoid downtime.

Example Settings for 1-Gallon Buckets

| Setting | Recommended Value |

|---|---|

| Label Size | 6 x 4 inches |

| Applicator Speed | 60 buckets/min |

| Adhesive Type | Permanent |

By embracing automation, you're not just saving time—you're also boosting the overall quality of your product line.

How Do You Label on Plastic 5-Gallon Jars?

The 5-gallon beast—now that's a whole different ballgame. I used to dread these until I learned a few tricks that made the process almost enjoyable.

To label plastic 5-gallon jars, use a specialized labeling machine capable of handling large, heavy containers. Ensure the machine has adjustable supports and applicators to accommodate the jar's dimensions for precise label placement.

Tackling the Giants

Labeling larger containers can feel like taming a dragon, but with the right equipment, it's entirely manageable.

- Heavy-Duty Machines: Invest in equipment designed for big jobs.

- Sturdy Conveyor Systems: Essential for handling the weight.

Lessons Learned

One time, we tried using our standard labeler for 5-gallon jars—it was a disaster. The machine struggled, and so did we. Upgrading was the best decision we made.

Key Considerations

- Safety First: Larger containers mean more weight—ensure all safety protocols are followed.

- Cost vs. Benefit: While the initial investment is higher, the efficiency gains are substantial.

Recommended Machine Features

| Feature | Specification |

|---|---|

| Machine Model | YCT-HeavyDutyLabeler |

| Max Jar Size | Up to 6 gallons |

| Speed | 30 jars/min |

It's amazing how the right tools can turn a daunting task into a straightforward one.

How to Labeling on Plastic Jars with Handle?

Handles can be a real headache—or so I thought until I discovered some clever solutions.

To label plastic jars with handles, use a labeling machine that can adjust for the handle's position. Modify the applicator settings to apply labels without obstructing or being obstructed by the handle.

Navigating Around Handles

Handles add complexity, but they're not insurmountable obstacles.

- Adjustable Applicator Arms: These can work around the handle.

- Sensor Technology: Some machines detect the handle's position for precise application.

A Handy Anecdote

I once spent hours trying to manually label jars with handles—never again. Upgrading our equipment was a game-changer.

Label Placement Strategies

- Opposite the Handle: Simplifies the process.

- Custom Labels: Designed to fit around handles.

Machine Features for Success

| Feature | Benefit |

|---|---|

| Handle Detection | Accurate label placement |

| Adjustable Labeling Head | Versatility with different jars |

| Custom Software | Tailored labeling processes |

With a bit of ingenuity, labeling jars with handles becomes just another part of the routine. Here is a video for your reference, my friend.

https://youtu.be/DOYBFGrvEo0

Conclusion

Labeling plastic buckets and jars doesn't have to be a chore. With the right equipment and a bit of know-how, it's a breeze. I've been down the road of trial and error, and if there's one thing I've learned, it's that investing in the right tools pays off—both in time saved and in the quality of the final product.

Remember, every challenge is just an opportunity in disguise. So go ahead, take the leap, and transform your labeling process. You'll thank yourself later.