Machine description:

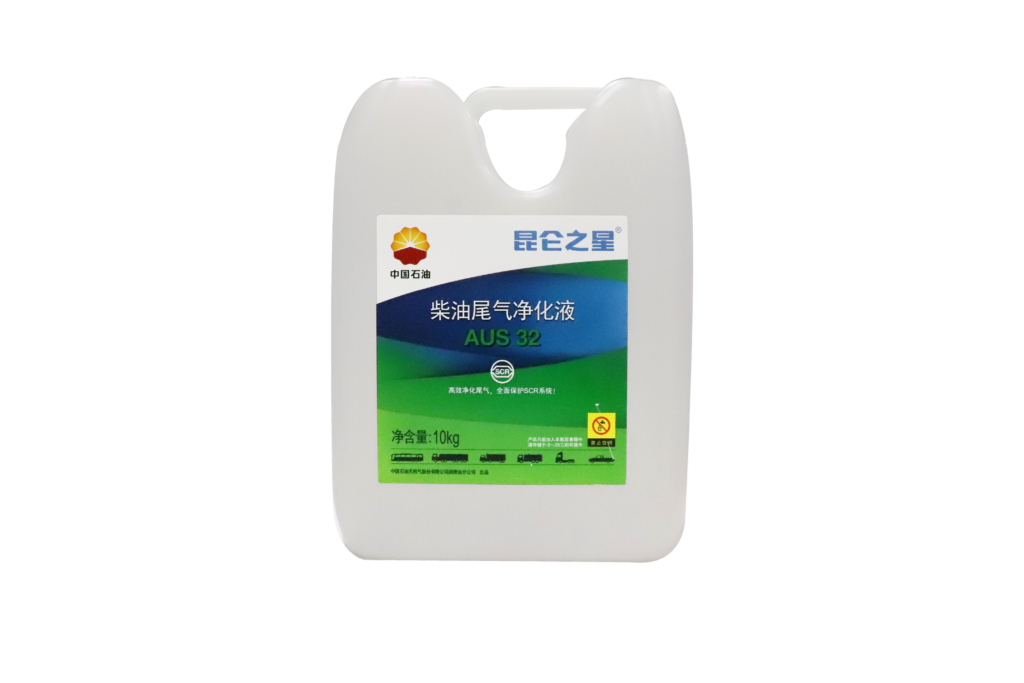

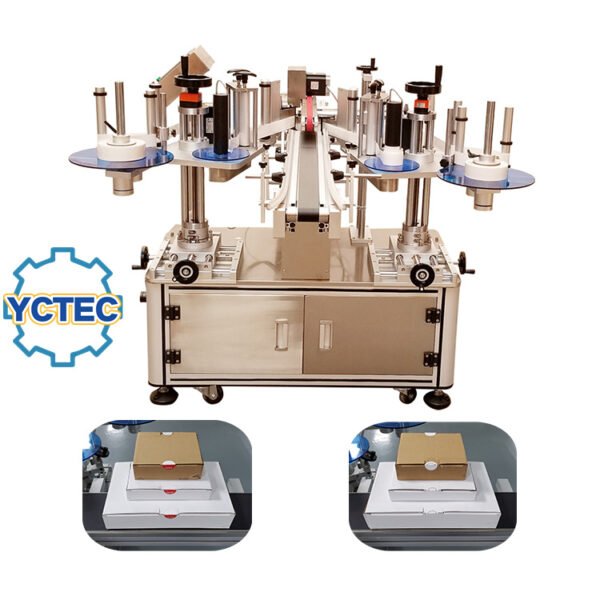

It is suitable for one-sided and two-sided labeling of flat bottles, round bottles and square bottles, such as shampoo flat bottles, lubricating oil flat bottles, hand sanitizer round bottles, etc. , Both sides are attached at the same time, double labels improve production efficiency, high-precision labeling, highlight the excellent quality of products, and improve competitiveness. It is widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

The additional functions to increase options:

Working principle: This part of the principle for our own research and development, if interested, welcome to consult.

Labeling Process:

Connect to production line/Feeding manually →The products are separated one by one →The product sensor detects the product→ PLC receives the product signal → Labeling→Collecting plate

Label requirements

Technical parameters:

| Parameter | Data |

| Label Specification | adhesive sticker, transparent or opaque |

| Labeling Tolerance | ±1 mm |

| Capacity(pcs/min) | 30~160 |

| Suit bottle size(mm) | L:20~250 W:30~100 H:60~280;Can be customized

(We can make it according to your sample diameter) |

| Suit label size(mm) | L: 15-200; W(H): 15-120 |

| Machine Size(L*W*H) | 3100*1450*1560 (mm) |

| Pack Size(L*W*H) | 3150*1500*1600 (mm) |

| Voltage | 220V/50(60)HZ;Can be customized |

| Power | 2070W |

| N.W (KG) | 330.0KG |

| G.W(KG) | 400.0KG |

| Label Roll | ID: Ø76mm;OD:≤300mm |

| No. | Name | Function |

| 1 | Conveyor | transmit product. |

| 2 | Double Side Guardrails | keep the products go straightly, can be adjusted according to product size. |

| 3 | Spacing Wheel | makes every 2 products keep certain distance. |

| 4 | Double Side Guiding Belt | correct product transmission direction, can be adjusted according to product size. |

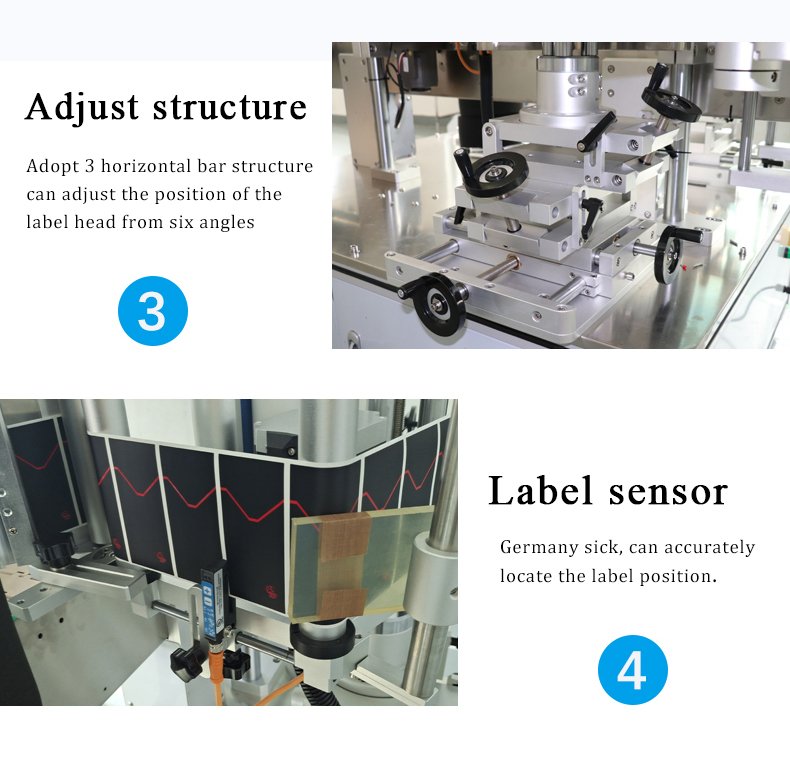

| 5 | Labeling Head | core of the labeler,includes label-winding and driving structure. |

| 6 | Double Sides Label-peeling Plate | peel label from the release paper. |

| 7 | Double Sides Brush | smooth the labeled surface. |

| 8 | Touch Screen | operation and setting parameters |

| 9 | Top Belt | synchronous with the conveyor and traction device, fix product from the top |

| 10 | Top Belt Adjuster | adjust the height of the top belt to adapt to different products. |

| 11 | Strengthening Device | Press labeled product to strengthen labeling. |

| 12 | Main Switch | Open the machine |

| 13 | Emergency Stop | stop the machine if it runs wrong. |

| 14 | Electric Box | place electronic configurations. |

1 ) Control System: Japan Panasonic control system , with high stability and extremely low failure rate.

2 ) Operation System: Touch screen , directly visual interface easy operation.Chinese and English available . Easily to adjust all electrical parameters and have counting function, which is helpful for production management.

3) Detection System: German LEUZE/Italian Datalogic label sensor and Japan Panasonic product sensor , which are sensitive to label and product , thus ensure high accuracy and stable labeling performance .

4) Alarm Function : The machine will give an alarm when problem occur , such as label spill , label broken , or other malfunctions .

5) Machine Material : The machine and spare parts all use material stainless steel and anodized senior aluminum alloy , with high corrosion resistance and never rust .

6) Equip with a voltage transformer to adapt to local voltage.

WhatsApp us