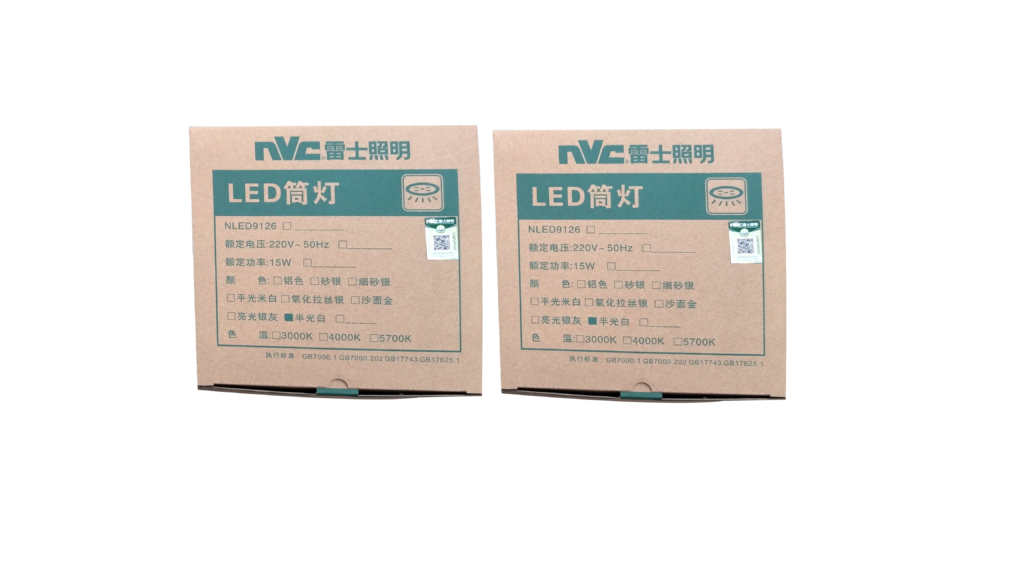

This machine can be matched to your production line to label the flowing products on the upper surface and the curved surface to realize online unmanned labeling. If it is matched to the coding conveyor belt, it can label the flowing objects. High-precision labeling highlights the excellent quality of products and enhances competitiveness.

It is widely used in packaging, food, toys, daily chemical, electronics, medicine and other industries.

The automatic line labeling machine has additional functions to increase options:

It is suitable for products that require large output, with high labeling accuracy of ±0.1mm, fast speed and good quality, and it is difficult to see the error with the naked eye.

working principle: The sensor detects the passing of the product and sends back a signal to the labeling control system. At the appropriate position, the control system controls the motor to send out the label and attach it to the labeling position of the product. The product passes the labeling roller, and a label The attaching action is completed.

Labeling Process:

Product (connected to the assembly line) —> product delivery —> product testing —> labeling.

Label production requirements

Technical parameters:

| Parameter | Date |

| Label Specification | Adhesive sticker, transparent or opaque |

| Labeling Tolerance | ±1mm |

| Labeling speed (pcs / min) | Step:40~150pcs/min

Servo:50~200pcs/min (influenced by the size of the product and label) |

| Suit product size(mm) |

No requirement. |

| Suit label size(mm) | L:10-250;W(H):10-120 |

| Machine Size(L*W*H) | 1100* 700*1450(mm) |

| Pack Size(L*W*H) | 1110*706*1460(mm) |

| Voltage | 220V/50(60)HZ; Be customized |

| Power | 300W |

| N.W(KG) | 75.0KG |

| G.W(KG) | 95KG |

| Label Roll | ID:Ø76mm; OD:≤280mm |

| No. | Structure | Function |

| 1 | Label Tray | place the label roll. |

| 2 | Rollers | wind the label roll. |

| 3 | Label Sensor | detect label. |

| 4 | Traction Device | driven by traction motor to draw the label. |

| 5 | Release Paper Recycling | recycle the release paper. |

| 6 | Product Sensor | detect product. |

| 7 | Emergency Stop | stop the machine if it runs wrong |

| 8 | Height Adjuster | adjust the height of labeling. |

| 9 | Electric Box | place electronic configurations |

| 10 | Frame | can be customized to adapt to production line. |

| 11 | Touch Screen | operation and setting parameters |

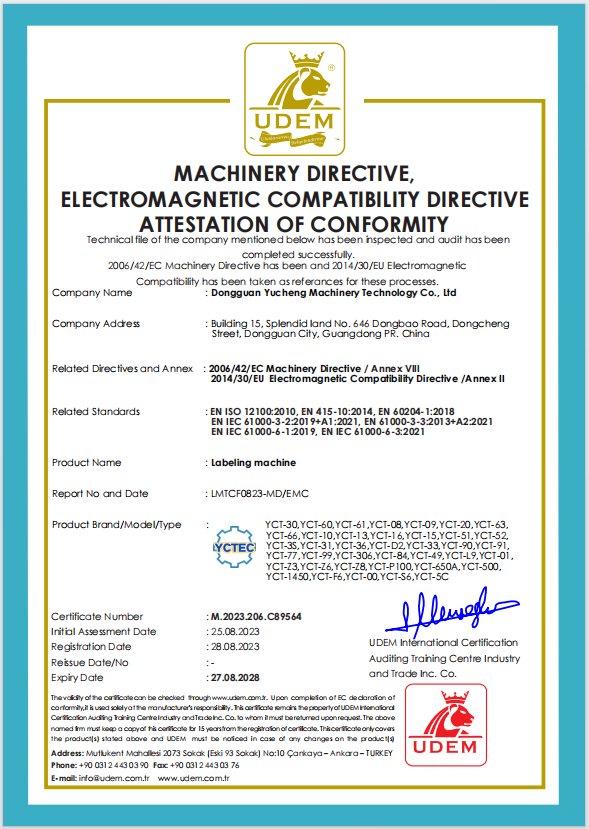

1 ) Control System: Japan Panasonic control system , with high stability and extremely low failure rate.

2 ) Operation System: Touch screen , directly visual interface easy operation. Chinese and English available . Easily to adjust all electrical parameters and have counting function , which is helpful for production management.

3) Detection System: German LEUZE/Italian Datalogic label sensor and Japanese Panasonic product sensor , which are sensitive to label and product , thus ensure high accuracy and stable labeling performance . Greatly saves labor .

4) Alarm Function : The machine will give an alarm when problem occur , such as label spill , label broken , or other malfunctions .

5) Machine Material : The machine and spare parts all use material stainless steel and anodized senior aluminum alloy , with high corrosion resistance and never rust .

6) Equip with a voltage transformer to adapt to local voltage.

WhatsApp us