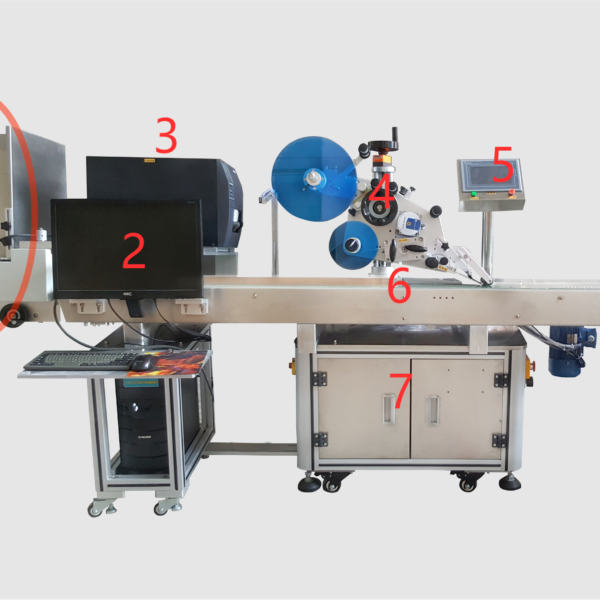

Real Time Printing Labeling Machine

Our Real-Time Printing Labeling Machine Series combines printing and labeling into one seamless operation, allowing for on-demand, high-precision label application. These machines are ideal for industries requiring dynamic data labeling, such as logistics, manufacturing, and retail. Enhance your production efficiency with our state-of-the-art real-time printing labeling solutions

Your Trustful Real Time Printing Labeling Machine

The Real-Time Printing Labeling Machine is designed for efficient and accurate on-demand labeling in various industries. It prints and applies labels in real time, ensuring up-to-date information for products, packaging, or logistics. This machine enhances production efficiency by seamlessly integrating into your workflow. Whether for barcode labels, shipping details, or product information, it delivers precision and speed. Explore our range of Real-Time Printing Labeling Machines below to find the perfect solution for your needs. Click on the products to learn more about their features and specifications!

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Real Time Printing Labeling Machine

The Real-Time Printing Labeling Machine is a versatile solution designed to print and apply labels instantly, meeting the dynamic needs of modern industries. It ensures accuracy, efficiency, and flexibility by allowing labels to be generated on-demand with real-time data, such as barcodes, product details, or shipping information. Perfect for manufacturing, logistics, and retail environments, this machine streamlines labeling processes, reduces downtime, and improves operational efficiency. With its user-friendly design and high-speed performance, it delivers consistent and precise labeling every time. Whether for small-scale operations or large production lines, this machine is the key to optimized workflow and improved productivity.

Advantages of Real Time Printing Labeling Machine

- High Efficiency

The Real-Time Printing Labeling Machine prints and applies labels instantly, reducing manual intervention and minimizing production downtime. This ensures seamless and faster labeling processes for high-volume operations.

- Accurate Labeling

With real-time data integration, labels are generated with precise and up-to-date information, reducing errors in product details, barcodes, or shipping information. Accuracy improves both product identification and workflow reliability.

- Enhanced Flexibility

The machine can adapt to different label sizes, shapes, and materials, making it suitable for diverse industries like manufacturing, logistics, and retail. It easily integrates with existing production lines for greater flexibility.

- Cost-Effective

By automating the labeling process, businesses can save on labor costs and reduce waste caused by incorrect or outdated labels. This improves operational cost efficiency over time.

- User-Friendly Operation

Designed with intuitive controls and software, the machine is easy to operate and maintain. Its real-time printing capability simplifies complex labeling tasks while ensuring smooth performance.

- Improved Productivity

The speed and precision of real-time labeling significantly enhance production throughput. This ensures businesses can meet deadlines, optimize workflows, and boost overall productivity.

How Do Real Time Printing Labeling Machines Work?

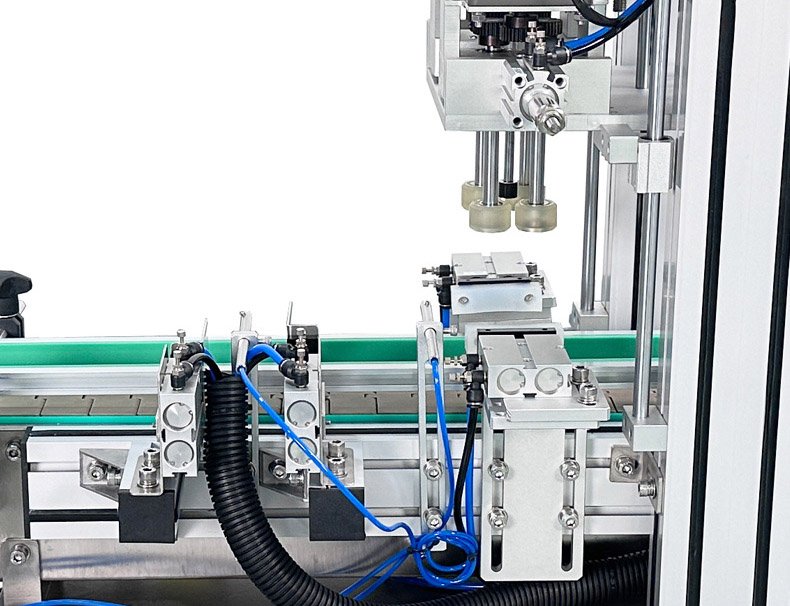

Real-Time Printing Labeling Machines operate by seamlessly integrating printing and application processes into one automated system. First, the machine receives real-time data, such as product details, barcodes, or shipping information, from a connected database or input system. It then prints the label on demand, ensuring the information is always accurate and up-to-date. Once printed, the label is immediately applied to the product, package, or container using a precise application mechanism like a tamp, blow, or wipe method. This automated workflow allows for continuous labeling with minimal human intervention, improving speed, accuracy, and efficiency across production lines.

What Are Real Time Printing Labeling Machines Used For?

Real-Time Printing Labeling Machines are used across various industries to print and apply labels with accurate, up-to-date information instantly. In manufacturing, they are ideal for product identification, lot numbers, and expiration dates. In logistics and warehousing, they streamline shipping, tracking, and inventory management with real-time barcode and address labeling. Retail businesses use them for price tags and product details, while in the food and beverage industry, they ensure compliance with labeling regulations by providing fresh production and expiration information. These machines are essential for improving efficiency, reducing errors, and ensuring smooth operations in dynamic production environments.

Design and Planning

Engineers start by designing the machine to meet specific needs, including label size, product dimensions, and production speed. CAD software is used to create detailed blueprints, ensuring precision and compliance with industry standards.

Material Selection

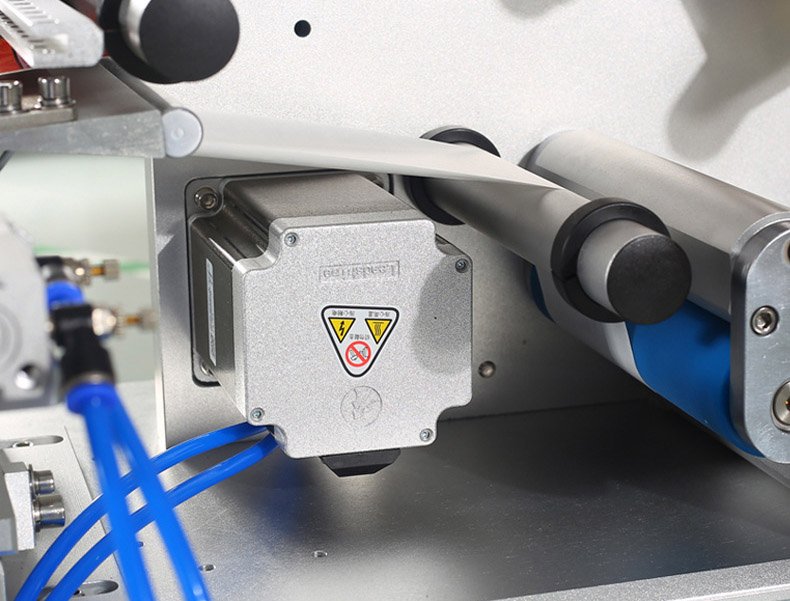

High-quality and durable materials, such as stainless steel and industrial-grade components, are chosen to ensure the machine’s longevity, stability, and ability to operate under high-speed conditions in demanding environments.

Component Manufacturing

Key components like printers, applicators, conveyors, and sensors are manufactured or sourced. Advanced techniques like CNC machining and precision molding are used to ensure parts are accurate and reliable.

Assembly and Integration

The machine’s components are assembled carefully, combining mechanical, electrical, and software systems. Real-time printers and application modules are integrated to work seamlessly for on-demand printing and labeling.

Testing and Quality Control

Once assembled, the machine undergoes rigorous testing to ensure functionality, speed, and accuracy. Quality control checks verify that it meets production standards, performs reliably, and operates without errors.

Installation and Training

After final approval, the machine is installed at the customer’s facility. Technicians provide training to operators, ensuring smooth operation, maintenance, and integration into existing production lines.

Real Time Printing Labeling Machine Designs: Factors to Consider

#1 Product Shape and Size Compatibility

Real-time printing labeling machines must accommodate a variety of product shapes and sizes while ensuring accurate label placement. The design includes adjustable fixtures and flexible application modules to handle products in dynamic production lines efficiently.

#2 Real-Time Data Processing

The machine must integrate seamlessly with databases, ERP, or WMS systems to process and print real-time data, such as barcodes, batch numbers, or expiration dates. The design ensures rapid data input and immediate printing without delays.

#3 High-Speed Printing and Application

To meet the demands of fast-paced production environments, the design prioritizes high-speed printing and label application. Advanced mechanisms ensure labels are printed and applied instantly, keeping up with real-time production speeds.

#4 Precision and Accuracy

The real-time nature of these machines requires precise synchronization between printing and application. Sensors and control systems ensure labels are placed accurately, even at high speeds, reducing errors and material waste.

#5 Connectivity and Integration

Real-time printing machines must be equipped with advanced connectivity features, such as Ethernet, Wi-Fi, or IoT capabilities. This allows for instant data transfer, remote monitoring, and seamless integration into automated production systems.

#6 Environmental Adaptability

The design accounts for real-time operations in various conditions, including temperature fluctuations and high humidity. Durable components and protective casings ensure reliable performance in challenging environments.

#7 User-Friendly Interface for Real-Time Monitoring

An intuitive user interface is crucial for real-time operation. Touchscreen controls and monitoring dashboards allow operators to view live data, adjust settings, and respond quickly to production changes or errors, ensuring uninterrupted workflows.

Real Time Printing Labeling Machine by Automation Classification

Semi-auto Real Time Printing Labeling Machine

As a leading provider in the labeling machine industry, YUCHENG has been serving a wide range of market sectors where precision labeling plays a vital role. These industries require advanced and efficient labeling solutions to optimize their operations and maintain the highest quality standards in production.

Automatic Real Time Printing Labeling Machine

As a leading provider in the labeling machine industry, YUCHENG has been serving a wide range of market sectors where precision labeling plays a vital role. These industries require advanced and efficient labeling solutions to optimize their operations and maintain the highest quality standards in production.

As a leading provider in the labeling machine industry, YUCHENG has been serving a wide range of market sectors where precision labeling plays a vital role. These industries require advanced and efficient labeling solutions to optimize their operations and maintain the highest quality standards in production.

Request A free quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 186 6414 0847

- Amy@3yct.com