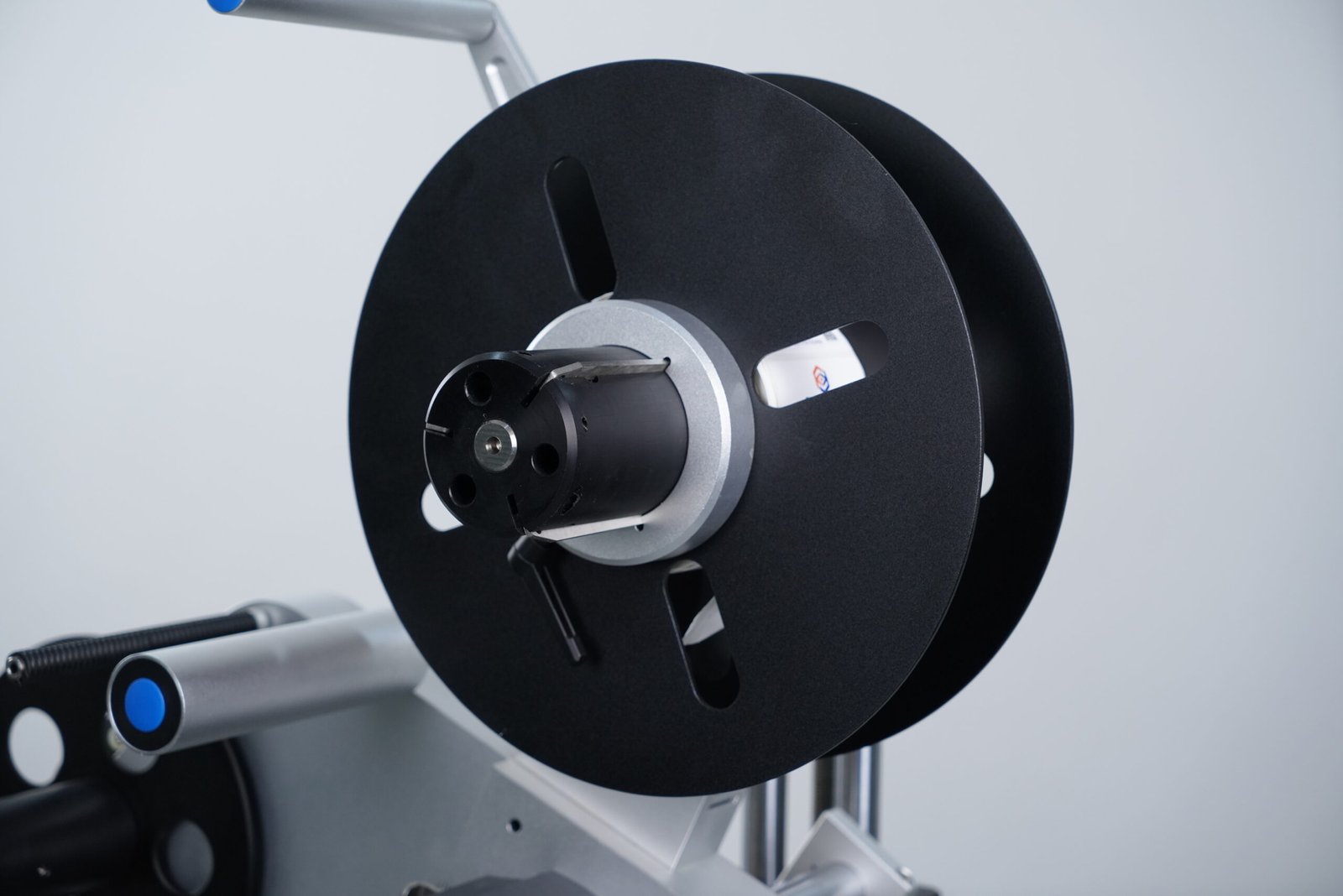

A high-speed label applicator is an automatic labeling machine designed to apply labels rapidly onto products or packaging. It significantly increases production efficiency by labeling thousands of items per hour. These machines are crucial in industries that require fast-paced labeling, such as food and beverage, pharmaceuticals, and cosmetics.

Let's dive deeper into how these machines work and why they're so important.

Which industries are high-speed labeling machines mainly used in?

From my experience, high-speed labeling machines are essential in several key industries.

High-speed labeling machines are mainly used in industries like food and beverage, pharmaceuticals, cosmetics, and consumer goods. These sectors require rapid labeling to keep up with high production demands, ensuring products are accurately labeled and ready for market.

It's widely used in the industries as below:

Food and Beverage Industry

In the food and beverage sector, speed and accuracy are crucial. High-speed label applicators, such as beer bottle labelers, ensure that products like beer bottles, cans, and packaged foods are labeled efficiently. Labels contain important information like ingredients, nutritional facts, and expiration dates.

Pharmaceutical Industry

Pharmaceutical companies require precise labeling for safety and compliance. Automatic labeling machines help in applying labels that include dosage information, batch numbers, and barcodes at high speeds, reducing the risk of human error.

Cosmetics Industry

Cosmetics products often come in various shapes and sizes. High-speed labeling machines can handle different packaging formats, applying labels quickly to items like bottles, tubes, and jars.

Consumer Goods

Everyday items like cleaning products, personal care items, and household goods need efficient labeling to meet market demands. High-speed labelers help manufacturers keep up with production volumes.

Here's a table summarizing the industries and their labeling needs:

| Industry | Labeling Needs |

|---|---|

| Food and Beverage | Nutritional info, branding, expiration dates |

| Pharmaceuticals | Dosage info, compliance labels, barcodes |

| Cosmetics | Branding, ingredient lists, safety warnings |

| Consumer Goods | Product info, usage instructions, safety warnings |

What is a high speed labeling machine used for?

You might be wondering what exactly these machines do on a production line.

A high-speed labeling machine is used to apply labels swiftly and accurately to products or packaging. It automates the labeling process, reducing manual labor and increasing production efficiency. These machines can handle various label types and product shapes, ensuring consistent and precise application.

Let's delve into how high-speed labeling machines function and their applications.

Automation and Efficiency

High-speed label applicators automate the labeling process, which is essential for large-scale manufacturing. By reducing the need for manual labeling, they minimize errors and speed up production lines. While the initial investment in an automatic labeling machine may seem high, the price is justified by long-term savings.

Versatility

These machines can handle different types of labels, such as pressure-sensitive labels, shrink sleeves, or wrap-around labels. They can also accommodate various product shapes and sizes, from bottles and cans to boxes and bags.

Precision and Consistency

Automatic labeling machines ensure that each label is applied in the correct position with consistent quality. This precision is vital for brand image and regulatory compliance.

Integration with Production Lines

High-speed labeling machines can be integrated into existing production lines. They often come with features like synchronization with conveyors, automatic label detection, and real-time adjustments.

Here's a table of key features:

| Feature | Description |

|---|---|

| Automation | Reduces manual labor and increases speed |

| Versatility | Handles various labels and product shapes |

| Precision | Ensures accurate label placement |

| Integration | Fits into existing production systems |

How fast is a labeling head speed?

Many people ask me just how fast a labeling head can operate.

A labeling head in a high-speed labeling machine can apply labels at speeds ranging from 100 to over 500 labels per minute. The exact speed depends on the machine's specifications and the product being labeled.

Understanding the speed capabilities of labeling heads is important for matching production needs.

Factors Affecting Speed

- Machine Specifications: Different models have varying maximum speeds.

- Product Size and Shape: Smaller or uniform products can be labeled faster.

- Label Size: Larger labels may take more time to apply.

- Accuracy Requirements: Higher precision may slightly reduce speed.

Typical Speeds

- Entry-Level Machines: Around 100-200 labels per minute.

- Mid-Range Machines: Approximately 200-400 labels per minute.

- High-End Machines: Over 500 labels per minute.

Here's a table summarizing speeds:

| Machine Type | Labels per Minute |

|---|---|

| Entry-Level | 0-40 |

| Mid-Range | 100-150 |

| High-End | 100-180 |

Importance of Speed

High-speed labeling ensures that the labeling process doesn't become a bottleneck in production. It's crucial for industries with high output demands.

Why is labeling important in marketing?

Labeling isn't just about compliance; it's a key part of marketing.

Labeling is important in marketing because it communicates brand identity, product information, and attracts customers. A well-designed label can influence purchasing decisions by providing essential details and appealing visuals that set the product apart from competitors.

Let's explore how labeling impacts marketing strategies.

Brand Identity

Labels carry logos, brand colors, and design elements that help consumers recognize products. Consistent labeling reinforces brand awareness.

Information Delivery

Labels provide critical information like ingredients, usage instructions, and benefits. This transparency builds trust with consumers.

Legal Compliance

Proper labeling ensures compliance with regulations, which is essential to avoid fines and maintain a good reputation.

Consumer Attraction

Eye-catching labels can draw attention on crowded shelves. Design elements like colors, fonts, and imagery play a significant role.

Influence on Purchasing Decisions

A label that clearly communicates value can sway a customer to choose one product over another. For example, highlighting eco-friendly materials or special features.

Here's a table highlighting labeling aspects in marketing:

| Aspect | Impact on Marketing |

|---|---|

| Brand Identity | Enhances recognition and loyalty |

| Information | Builds trust through transparency |

| Compliance | Avoids legal issues, maintains reputation |

| Attraction | Draws consumer attention, differentiates product |

| Decision Influence | Encourages purchases through clear messaging |

Conclusion

High-speed label applicators are vital in modern manufacturing, improving efficiency and supporting marketing efforts. Understanding their role can help businesses optimize production and stand out in the market.