Wire Folding and Labeling Machine

Our wire folding and labeling machines streamline the process of folding and labeling wires, ensuring accuracy and efficiency. Ideal for industries such as electronics and manufacturing, these machines improve productivity while maintaining high precision. Enhance your wire processing operations with our advanced folding and labeling solutions

Your Trustful Wire Folding and Labeling Machine

The Wire Folding and Labeling Machine is engineered to streamline the process of folding and labeling wires with precision and efficiency. Ideal for industries such as electronics, electrical manufacturing, and cable production, this machine automates the folding and labeling stages, ensuring consistent and accurate labeling on each wire or cable. The machine offers a seamless integration of both functions, enhancing productivity while reducing the need for manual labor. With its adjustable settings, it can accommodate various wire sizes and types, providing a flexible and reliable solution for high-speed, high-precision production lines. Whether for packaging or quality control, this machine ensures flawless results, improving both throughput and quality in wire manufacturing.

REQUEST A QUOTE FOR MORE DETAILS

All You Need to Know About Wire Folding and Labeling Machine

The Wire Folding and Labeling Machine is designed to automate both the folding and labeling of wires, making it an essential tool for industries that require precise labeling on long, flexible materials. This machine improves production efficiency by performing both tasks simultaneously, reducing the time spent on manual labor and minimizing the chances of errors.

The system uses adjustable settings to accommodate different wire sizes and label types, ensuring high versatility across a range of applications. Perfect for electrical and electronic industries, the Wire Folding and Labeling Machine increases throughput, maintains consistent labeling quality, and contributes to an organized and efficient production line.

Advantages of Wire Folding and Labeling Machine

- Increased Efficiency

The Wire Folding and Labeling Machine automates the folding and labeling process, eliminating the need for manual intervention and speeding up production. This results in improved throughput and overall efficiency.

- High Precision

With advanced sensors and controls, this machine ensures that labels are applied accurately and consistently on each wire, preventing misplacement and ensuring quality labeling.

- Versatility

It is designed to handle various wire sizes, types, and label materials, offering flexibility for different applications in the electrical and electronics industries.

- Reduced Labor Costs

By automating both folding and labeling processes, the machine reduces the reliance on manual labor, lowering operational costs and minimizing human errors.

- Space-Saving Design

The integrated folding and labeling system minimizes space usage on the production floor, making it ideal for environments with limited space while maintaining productivity.

- Production Flow

With its ability to fold and label wires in one continuous process, the machine streamlines production, reducing time spent on handling and reworking products and ensuring a smoother workflow.

How Do Wire Folding and Labeling Machine Work?

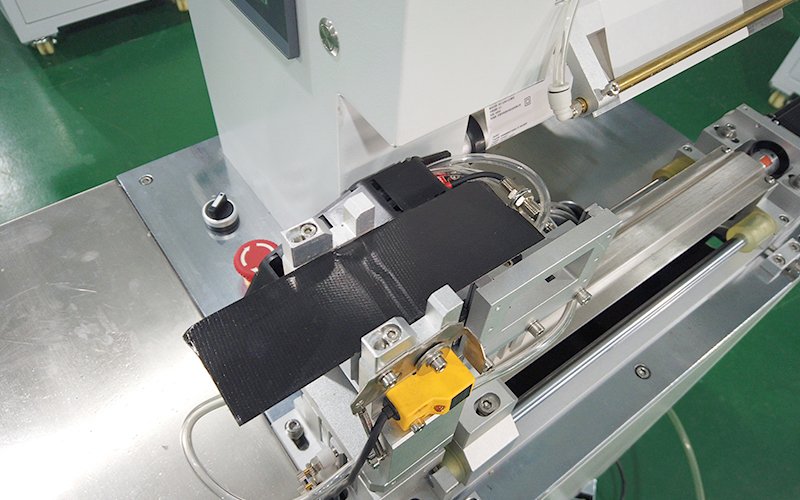

The Wire Folding and Labeling Machine works by first feeding the wire into a set of rollers that fold it to the required specifications. Once folded, the wire moves into the labeling section where it is aligned by sensors to ensure precise placement. The machine then applies labels to the wire using an applicator that places them with high accuracy.

The labeling process can be adjusted to accommodate different wire types and label sizes, ensuring the correct label is applied each time. After the wire is labeled, it continues on the conveyor system for further processing or packaging. The machine is equipped with various sensors, pressure rollers, and adjustable settings for precise folding and labeling operations.

What Are Wire Folding and Labeling Machines Used For?

Wire Folding and Labeling Machines are used primarily in industries that require accurate labeling on wires and cables, such as electronics, electrical manufacturing, and automotive production. These machines are ideal for folding long wires or cables into standardized lengths and then applying labels for product identification, tracking, or branding.

They are widely used for labeling wires with barcodes, part numbers, or compliance certifications, ensuring that the wires are easily traceable throughout the production process and into the supply chain. The machine’s ability to automate both folding and labeling processes significantly increases productivity and reduces the likelihood of labeling errors.

Design and Planning

Engineers begin the design process by determining the specific needs of the customer, including the wire sizes, label types, and production speeds. They create detailed blueprints using CAD software to ensure the machine meets operational requirements and efficiency goals.

Component Manufacturing

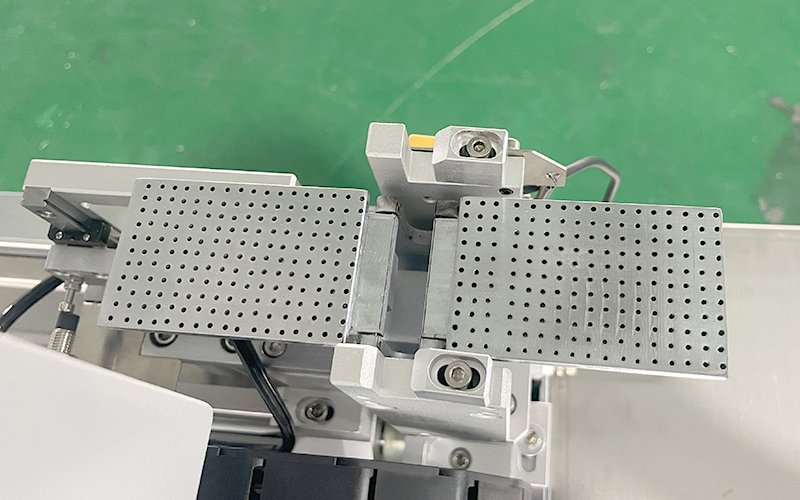

Once the design is finalized, the machine components are fabricated. These include folding mechanisms, label applicators, sensors, and electrical systems, all manufactured with precision to ensure optimal performance.

Assembly

The individual components are assembled, ensuring that all parts fit together perfectly for smooth machine operation. The folding and labeling units are carefully aligned to achieve accurate results during production.

Software Integration

The machine’s software is programmed to control the labeling process, manage sensor data, and allow for easy adjustments of folding and labeling parameters, ensuring flexibility for different product types.

Testing and Calibration

Before the machine is ready for use, it undergoes extensive testing to ensure that it operates correctly. Calibration is performed to fine-tune the folding and labeling accuracy, ensuring consistent results.

Quality Control and Inspection

After the machine has passed testing, it undergoes a thorough inspection to ensure it meets the necessary safety and quality standards. Any necessary adjustments are made before the machine is shipped to the customer.

How Are Wire Folding and Labeling Machines Made?

Packaging and Delivery

Once all tests and inspections are complete, the Wire Folding and Labeling Machine is carefully packaged for delivery. Manuals, maintenance guides, and necessary documentation are included to assist with installation and setup.

Wire Folding and Labeling Machine Designs: Factors to Consider

#1 Wire Size and Material

The design must accommodate a wide variety of wire types, from thin cables to thicker industrial wires. Adjustable folding mechanisms and custom conveyors ensure accurate handling and labeling of different wire sizes.

#2 Labeling Precision

The machine design must ensure that labels are consistently applied in the correct position on the wire, without shifting or misalignment, to maintain accuracy and high-quality standards.

#3 Production Speed

To meet the needs of high-volume production environments, the design should optimize labeling and folding speeds, reducing cycle times without compromising quality.

#4 Flexibility and Customization

The machine should be designed with flexibility in mind, allowing adjustments to handle various wire types and label formats. Customizable settings help adapt to different applications and production requirements.

#5 Durability

The machine should be made of durable materials that can withstand continuous operation in industrial environments, minimizing the need for maintenance and ensuring longevity.

#6 Space Efficiency

The design should minimize space usage on the production floor, especially in facilities with limited space. A compact yet effective layout ensures optimal use of available floor area.

#7 Ease of Operation

The machine should feature an intuitive control system, making it easy for operators to adjust settings and monitor performance. The interface should be user-friendly and require minimal training.

Wire Folding and Labeling Machine by Automation Classification

Semi-auto Wire Folding and Labeling Machine

The Semi-Automatic Wire Folding and Labeling Machine is designed for smaller production runs or businesses with moderate labeling needs. In this setup, the operator manually places the wire into the folding mechanism, after which the machine automatically handles the folding and labeling. This system offers greater flexibility compared to fully manual operations while still reducing the labor required for these tasks. It’s ideal for businesses that need precise labeling but don’t require the high output of fully automatic systems.

Automatic Wire Folding and Labeling Machine

The Fully Automatic Wire Folding and Labeling Machine is designed for high-volume production environments. The machine automates the entire folding and labeling process, from wire feeding to final labeling, with minimal operator intervention. It offers high-speed, precision labeling and is equipped with advanced sensors and controls that can adapt to different wire sizes and label formats. This machine is ideal for large-scale production lines where efficiency, accuracy, and high throughput are critical. It minimizes labor costs, maximizes productivity, and ensures consistent quality in labeling.

Request A free quote

We'd like to work with you

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

- +86 186 6414 0847

- Amy@3yct.com